Application of Zirconia Ceramic Conversion Coating in Automobile Coating

2020-09-16(3569)Views

1. The principle of zirconia ceramic film formation

Zirconium oxide ceramic film formation technology is "one-step film formation", which means that the metal surface is treated with a surface treatment agent. Schematic diagram of the formation of zirconia ceramic film on the surface of iron and steel. The main materials are fluorozirconic acid and zirconium salt. Fluorozirconic acid and zirconium salt directly react with the metal substrate. The resulting zirconia ceramic film adheres to the surface of the metal substrate to prevent corrosion effect.

Currently, the sol-gel method is the most important method for producing zirconia conversion coatings. The so-called sol-gel means that the colloidal particles are cross-linked together to form a three-dimensional network configuration, which can mechanically wrap a large amount of solvent inside the aggregate so that it no longer flows, becomes a semi-solid state, and becomes a gel. When the density of the sol particles in the colloidal solution is greater than that of the solution, under the action of gravity, the sol particles have a tendency to sink. If some parameters in the solution are changed so that the deposition rate of colloidal particles is greater than the diffusion rate, the colloidal particles will quickly precipitate out of the solution. The chemical reaction equation of zirconia conversion film technology is as follows:

where M=Fe, Zn, Al, Mg

The above reaction will form a "ZrO2-M-ZrO2" sol structure, which has a high cross-linking density and continues to condense and deposit, eventually producing a ZrO2 nano-ceramic conversion film.

2. Characteristics of zirconia ceramic membrane

In terms of film performance, the ceramic coating formed by the zirconia conversion film can completely replace the traditional phosphating film. In addition, the zirconia conversion film also has the characteristics of light weight, and its film thickness is about 50nm. Low film thickness means low film weight. The weight of traditional phosphating film is usually 2-3g/m2, and the film weight of zirconia conversion film is only 20-200mg/m2. Due to the different raw materials provided by the supplier, the weight of zirconia conversion film The film weight is also different, but overall, it is about 200 times lower than the traditional phosphating film. Shown is the X-ray photoelectron spectrum of the new zirconia conversion film on the galvanized steel sheet. From the figure, it can be seen that the thickness of the zirconia conversion film produced in the laboratory of Chery Automobile Company can be reduced to 30-35nm.

In terms of the process flow, the new zirconia conversion membrane technology is simpler and faster. Generally, it only takes about 30s to form a complete membrane, which can greatly reduce the cost of water consumption, waste water treatment, energy and manpower. They are the traditional phosphating process flow chart and the zirconium oxide conversion coating process flow chart.

It can be seen from the comparison that the new zirconia conversion coating replaces the traditional surface conditioning, phosphating and passivation processes, shortens the process flow, and reduces investment and process control costs. At the same time, the new process is suitable for a variety of metals (Fe, Zn, Al, Mg), so all kinds of plates can be processed in a mixed line. During processing, there is no waste formation of galvanized sheets and aluminum sheets, and only when cold-rolled sheets are processed A small amount of slag, but the waste slag produced can be easily removed by the traditional phosphating slag removal system, will not block the nozzle, and will not have any negative impact on the coating performance and the appearance of the electrophoretic coating.

In the required investment equipment, it is basically compatible with the original coating process and coating equipment, and no major equipment transformation is required.

In daily process management, the bath solution of the new zirconia film-forming technology is very stable and easy to control. In normal production, only the temperature and pH value need to be controlled. Unlike zinc phosphating, the total acid and free acid are regularly tested every day. And many parameters such as zinc, nickel, manganese content, save a lot of process management costs.

Zirconium oxide film forming technology has been applied earlier in foreign countries, and the German Henkel Group has the absolute right to speak in this field. In 2002, Henkel took the lead in introducing zirconium pretreatment materials suitable for a variety of plates; in 2008, GM adopted Henkel’s zirconium pretreatment materials at its San Jose Dos Campos plant in Brazil. At the same time, Ford TwinCity plant also Use Henkel's pre-treatment materials.

Domestically, until 2013, Qoros Motors adopted the zirconia conversion film automotive pretreatment technology for the first time in the domestic automotive production line.

3, summary

The dual demand of "environmental protection + energy cost" promotes the continuous development of green coating technology. The coating process and its equipment investment are the most energy-consuming and the largest part of the automobile factory, and the pre-treatment conversion film material is the automobile coating The key link. Compared with the traditional phosphating process, the zirconia ceramic conversion coating has the characteristics of light weight and fast production while ensuring the basic performance requirements. In addition, the phosphating to zirconium conversion process is simpler and the daily process management is simplified. It has been recognized by the three parties including OEMs, suppliers, and coating material companies. The zirconia ceramic film formation technology represented by "phosphorus-free film formation" has become the development trend of green coating.

+MoreRelated Suggestion

-

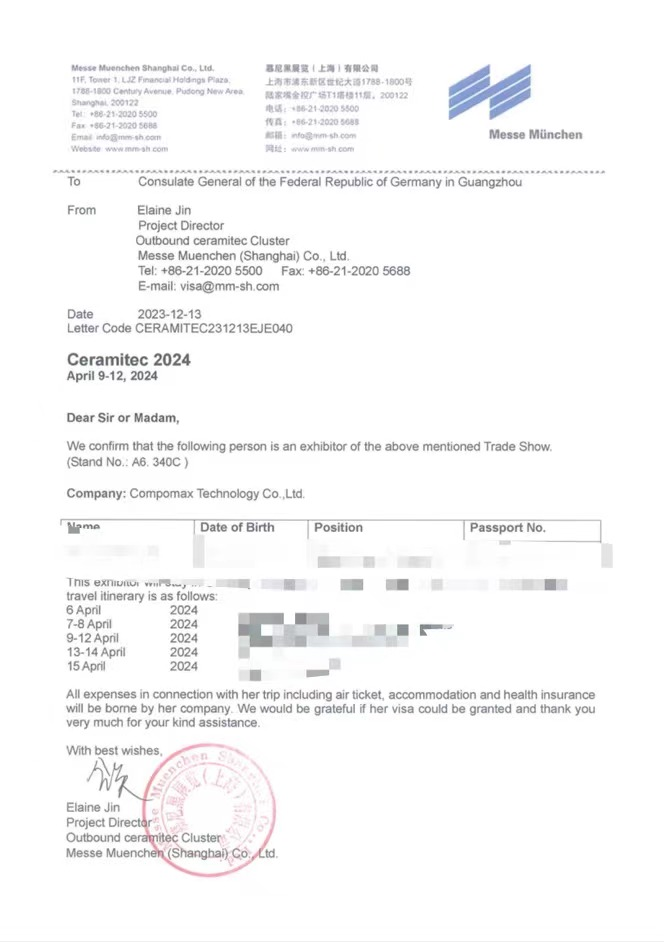

Compomax to Attend Ceramitec 2024

As a leading manufacturer of technical ceramics in China, Co...

-

PWTC Expo, the Exhibition Venue of CERAMICS CHINA 2024

From June 25-28, 2024, the 38th edtion of CERAMICS CHINA wil...

-

The eight application fields of zirconia ceramics in modern life

The non-signal shielding of zirconia ceramics is resistant t...

-

Application of Zirconia Ceramic Conversion Coating in Automobile Coating

In the field of automotive coating, phosphating is the most ...

0755-27688979

Service Hotline:0755-27688979

Phone:0086 13823743080

Fax:

Email:apricot@cpmic.com

Address: